How does it work?

Industrial heat pumps actively recover waste heat. The system is rather simple: heat pumps increase the temperature of waste heat streams to a higher temperature, making those streams usable again. A heat pump supplies heating and cooling at the same time.

The heat pump operates on the basis of a working fluid (refrigerant) which changes state (liquid/gas) in a continuous cycle and absorbs and releases heat (Carnot cycle).

Heat pumps can find application in numerous industrial processes and are particularly efficient when direct heat exchange is not possible, going even beyond a closed circuit and allowing the creation of an integrated system with different processes or users.

The process:

-

Evaporation

In the evaporator, the refrigerant is exposed to the heat source (e.g. industrial waste heat). There, the refrigerant evaporates at low pressure and low temperature.

-

Compression

The compressor increases the pressure of the refrigerant to a higher pressure and temperature level.

-

Condensation

In the condenser, the energy of the working fluid (refrigerant) is transferred to a distribution medium (e.g. water, steam or air) or a heat consumer. The refrigerant is cooled and becomes liquid again.

-

Expansion

In order to close the heat pump loop, the working fluid is fed into an expansion valve. The low pressure low temperature liquid is ready to enter the evaporator again.

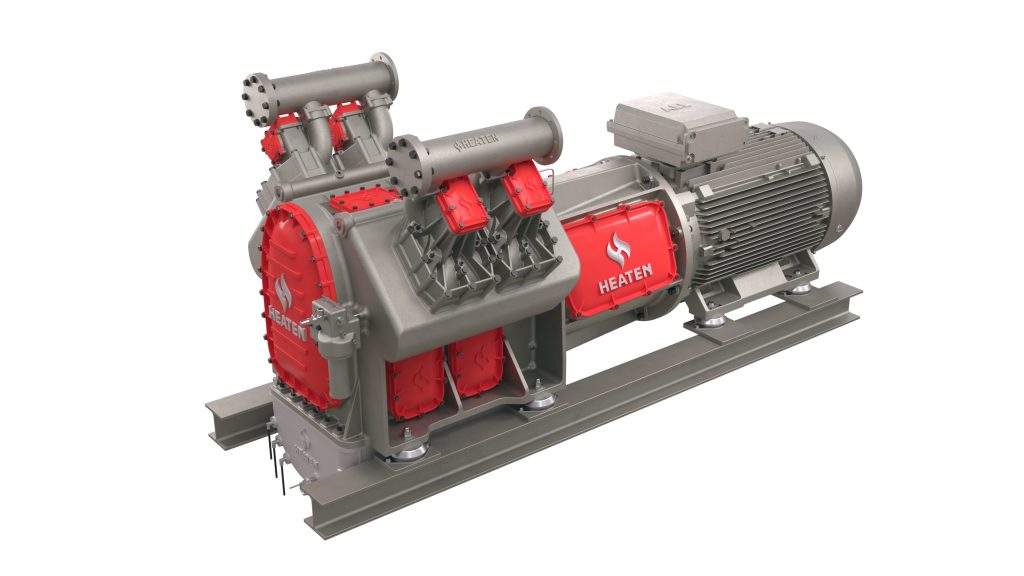

Unique for Heaten's piston compressor

-

Flexible

Largest flexibility regarding temperatures and load range. Easy to optimize based on operating temperatures. Different cylinder versions enable adaptations to each application.

-

Working Fluids

Fully free to choose from a range of working fluids. Independent from compressor design (versus e.g. turbo, piston is the only technology that can have a variable compression ratio). Design allows to use different HFO's and HC's with a low Global Warming Potential (GWP).

-

Efficiency

Efficiency curve is almost “flat” over 20 – 100% load range. Technology platform is already designed and tested for 215°C. Piston machines typically have mechanical efficiencies higher than 90%.

-

Durability

Heavy-Duty building on technology which is used to much higher temperatures. Heavy duty design to deliver 80,000 hours runtime between major overhauls. Heaten IP key to durability of high viscosity oil through separation of refrigerant and lubricants.

-

Serviceability

A piston compressor is a globally known technology. Access to qualified service and maintenance personnel in ubiquitous.

-

Scalability

Heaten's compressor uses similar components compared to a Heavy-Duty combustion engine. This guarantees fast production scalability at low costs.

Heaten today

With 13 years of R&D, design and engineering experience, Heaten has 3 years head start on the competition

June 2023

Demonstrated operation of first HBL4.

May 2023

Testbed facilities are ready in Remscheid, Germany.

June 2022

Detailed design freeze and production of pilot units starts.

January 2022

Heaten signs production agreement with AVL-Schrick.

2020-2021

Development of a large scale VHTP technology platform HeatBooster. The multi-cylinder platform allows up to 8 MWth per HeatBooster and more than 50 MWth per system.

2016-2017

Development of the HBS4, a commercial VHTHP with up to 200 kWth of output heat supply.

2015-2017

Development of pilot for Industrial Very-High-Temperature Heat Pumps (VHTHP), the “HeatBooster”, based on existing technology platform for ORC.

2015-2017

5th generation valve systems and large piston machine design based on established technology platform.

2014-2016

4th generation ORCs (10 kWel and 40 kWel systems) based on the required improvements to the demonstrator base design and provide commercially available systems.

2013-2014

3rd gen. Development of “commercial”-grade ORC demonstrators (10 kWel, index ‘el’ electric output) to mimic realistic customer requirements, and to execute extensive performance and durability testing.

2012-2013

2nd gen. ORC. Moving to a professional design process by collaboration with AVL/AVL Schrick and continued collaboration with DTU/IPU, which lead to the development, manufacturing and testing of Prototype B.

2011-2012

1st generation ORC.

2010-2011

Assess scientific evidence for developing a small-scale ORC (Organic-Rankine Cycle) for various markets.

Industries & processes

Industry needs Heaten’s technology to efficiently deliver processes heat above 130 °C.

See all industries

Pulp & Paper

- Drying

- Steam supply

Food & Beverages

- Distillation

- Pasteurization

- Sterilization

- Drying

- Spray Drying

- Blanching

- Concentration

- Smoking

- Boiling

- Evaporation

- Scalding

- Tempering

Chemicals

- Distillation

- Compression

- Thermoforming

- Concentration

Automotive

- Resin moulding

- Paint drying